Categories

Robot Guidance Rail

Key words:

Robot Rail

Classification:

Product Description

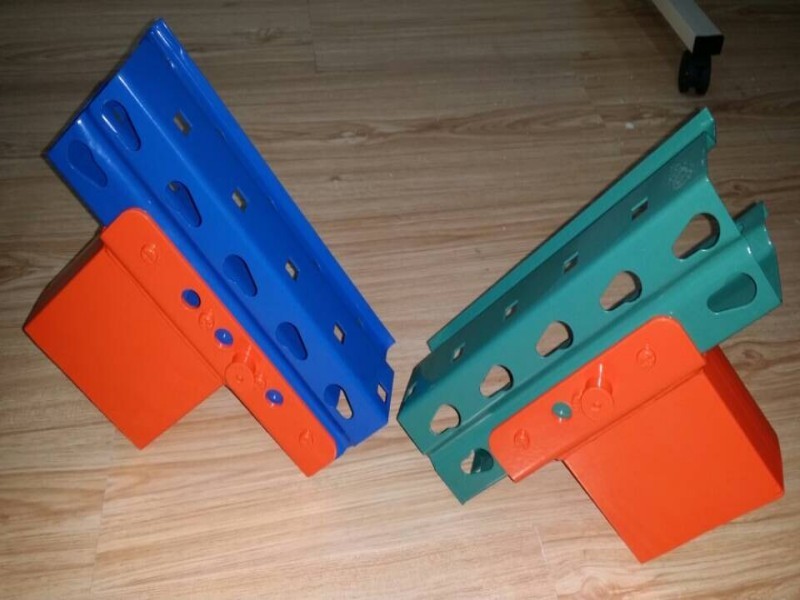

Robot Rail

Description:

The Robot Rail is an innovative and highly efficient storage solution designed to enhance automated warehouse operations. This system is ideal for businesses looking to integrate robotic automation for material handling, offering improved efficiency and faster retrieval times. The Robot Rail supports the seamless movement of robotic arms or automated guided vehicles (AGVs) to quickly access stored items, optimizing space utilization and workflow in warehouses, distribution centers, and manufacturing facilities.

Key Features:

Automated Movement: The Robot Rail system facilitates the movement of robotic arms or automated vehicles along fixed tracks, allowing for efficient and precise item retrieval and storage.

Space Optimization: By utilizing vertical space and allowing robots to access high-density storage, the Robot Rail system maximizes storage capacity without the need for additional floor space.

Scalable Design: The system is highly adaptable and can be scaled to suit a variety of warehouse sizes and operational needs, providing flexibility for growing businesses.

Durable Construction: Built with high-quality materials, the Robot Rail is designed to handle heavy-duty use in demanding environments, ensuring long-term reliability.

Increased Productivity: The automated nature of the system reduces manual labor, speeds up operations, and minimizes human error, allowing businesses to streamline their workflow and increase overall productivity.

Compatibility with Robotics: The Robot Rail is designed to integrate with various robotic systems, including Automated Guided Vehicles (AGVs) and robotic arms, offering seamless automation and control.

Benefits:

Higher Efficiency: The automated operation of the Robot Rail system accelerates inventory retrieval and storage, significantly reducing wait times and improving order fulfillment speed.

Cost-Effective Automation: Reduces the need for manual labor and increases storage capacity without requiring major infrastructure changes, providing a cost-effective automation solution.

Improved Accuracy: Automation reduces the risk of human error, ensuring accurate inventory tracking and consistent operations.

Flexible and Scalable: The system can be customized to meet specific storage needs and expanded as the business grows, offering long-term adaptability.

Applications:

- Warehouses and distribution centers

- Manufacturing and assembly lines

- E-commerce and retail fulfillment

- Automated storage and retrieval systems (ASRS)

- Logistics and inventory management

Specifications:

Dimensions: Customizable to fit your specific warehouse layout and storage requirements.

Load Capacity: Designed to handle various load capacities depending on the needs of your operation.

Material: High-strength steel for durability and performance under heavy loads.

Related Products